Thermal Imaging Inspections [1.8]

CRM Cyprus Ltd provides full thermographic imaging services using advanced technology IR scanning cameras. Measurements are conducted by certified thermographers.

Thermography (or Thermal Imaging or Infrared Scanning) is a relatively recent commercially available technology that allows thermal energy emission imaging and measurement via a thermal imaging camera.

The specific technology is based on the property of a body to emit IR radiation that become more intense as its temperature rises.

In this way thermographic imaging allows thermographic monitoring:

- Of all electrical installations that may be used for preventive maintenance, breakdown prevention, even electrical load distribution and fire safety

- Of all structures to determine thermal losses so that measures may be implemented

Electrical Installations [1.8.1]

Electrical Installations

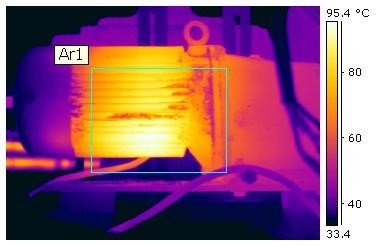

Among the maintenance applications IR scanning of electromechanical equipment is most important that predicts electrical failures or malfunctions allowing the early implementation of preventive technical measures without equipment shutdown.

With the use of thermo-sensitive equipment the installations under study are scanned periodically and an image is produced that reveals the higher-than-normal temperature areas that are susceptible to failure. In this way, appropriate measures can be applied depending on the type of temperature extremes.

It is worth noting that the most important part of IR scanning is not just spotting the “white” i.e. the “hot spot” area, but to evaluate the severity of the problem. This method is the ideal way to determine substandard parts of electrical equipment due to poor design or degradation as a result of corrosion, normal wear and tear, fatigue, misalignment that may raise internal resistance thus causing overheating. In general, IR scanning identifies problematic areas without physical contact making this preventive maintenance method safer for the operators without interrupting the installation’s operation.

CRM Cyprus Ltd conducts IR scans by certified thermographers.

Building Applications [1.8.2]

Building Applications

In buildings IR scanning assists in determining energy losses, detecting area and installation leaks, fugitive emissions, material permeability etc.

Poor construction of structural elements like openings, insulation panels, walls etc. present intense temperature differences when not constructed properly or when they are degraded in time, thus being easily detected by IR scanning. Readily and reliably spotting the problem means easier, cheaper and sooner repairing only the problematic area. IN several cases the method reveals the problem source.

Special areas like deep freeze, refrigerators, computer rooms etc. in which a standard temperature is an important parameter, IR scanning may accurately reveal the energy inefficient structural elements or leaking spots like cracks and crevices so that repair could be applied.

IR scanning presents so many advantages that it is always cost effective.

CRM Cyprus Ltd conducts IR scans by certified thermographers.

Electrical Installations [1.8.1]

Electrical Installations

Among the maintenance applications IR scanning of electromechanical equipment is most important that predicts electrical failures or malfunctions allowing the early implementation of preventive technical measures without equipment shutdown.

With the use of thermo-sensitive equipment the installations under study are scanned periodically and an image is produced that reveals the higher-than-normal temperature areas that are susceptible to failure. In this way, appropriate measures can be applied depending on the type of temperature extremes.

It is worth noting that the most important part of IR scanning is not just spotting the “white” i.e. the “hot spot” area, but to evaluate the severity of the problem. This method is the ideal way to determine substandard parts of electrical equipment due to poor design or degradation as a result of corrosion, normal wear and tear, fatigue, misalignment that may raise internal resistance thus causing overheating. In general, IR scanning identifies problematic areas without physical contact making this preventive maintenance method safer for the operators without interrupting the installation’s operation.

CRM Cyprus Ltd conducts IR scans by certified thermographers.

Building Applications [1.8.2]

Building Applications

In buildings IR scanning assists in determining energy losses, detecting area and installation leaks, fugitive emissions, material permeability etc.

Poor construction of structural elements like openings, insulation panels, walls etc. present intense temperature differences when not constructed properly or when they are degraded in time, thus being easily detected by IR scanning. Readily and reliably spotting the problem means easier, cheaper and sooner repairing only the problematic area. IN several cases the method reveals the problem source.

Special areas like deep freeze, refrigerators, computer rooms etc. in which a standard temperature is an important parameter, IR scanning may accurately reveal the energy inefficient structural elements or leaking spots like cracks and crevices so that repair could be applied.

IR scanning presents so many advantages that it is always cost effective.

CRM Cyprus Ltd conducts IR scans by certified thermographers.